1. Why is it necessary to improve power quality?

Electricity is an indispensable energy in our lives. The question is: “Why is it necessary to improve the power quality of the plant?” and “Are solutions to improve power quality for the plant necessary?”. VG Group can list some of the following reasons for you:

- Electricity quality directly affects modern production processes.

- Power quality directly affects the operation and lifespan of the device.

- Power quality is always the top concern of equipment manufacturers.

- The requirement to provide customers with the highest quality of electricity is the goal of electric utilities.

- Society's concern for electricity quality is increasingly increasing. Therefore, it is necessary to periodically assess power quality to take remedial measures when necessary/

- Poor power quality will cause harmonic disturbances and voltage flicker, negatively affecting electrical systems such as: electric motors and generators, transformers, cables, capacitors, electronic devices, and equipment. Protection measurement equipment, steel furnaces, product quality, neighboring electricity users, power grid system,...

Power quality is related to all production activities

2. Solutions to improve power quality for the factory

In order for electrical equipment to operate efficiently, correctly and at its best, you can refer to the following safe power quality solutions:

2.1 Improve cos phi power factor

This is one of the important measures to improve power quality for the plant to save electricity. When the cos phi power factor is raised, it will bring certain effects such as:

- Reduce power loss on the power network

- Reduces voltage loss in the electrical network

- Increase transmission capacity of lines and transformers

- Helps reduce non-ferrous metal costs

- Contributes to stabilizing voltage

- Increases generator detection capabilities

2.2 Economic operating mode of transformers, to reduce power loss

The next safe power quality solution that is also extremely effective is that the transformers in the stations need to have a reasonable working mode.

- Do not overload lines or transformers.

- Do not let load transformers operate out of phase.

- Ensures optimal operation

- Regularly monitor the cosφ of nodes on the power grid, measure the location and optimal capacitor design capacity to decide on the appropriate installation, conversion and operation of capacitors on the grid to reduce power loss.

- Check and maintain the power grid in good operating condition, comply with the grid maintenance inspection to ensure technical operating standards.

- Implement well the work of maintaining operating techniques to prevent incidents.

- Carry out economical operation of the transformer.

- Limits unbalanced components and high-order harmonics.

- Gradually eliminate unreliable, poor performance, high loss equipment with new high performance, low loss equipment (especially with MBA).

Replacing low-performing equipment helps reduce power loss

2.3 Handle harmonics, reduce power loss

Harmonic handling is one of the most effective measures to improve power quality for businesses and factories.Harmonics are often very rarely detected, the harmful effects of harmonics are often great and cause many serious consequences. Devices have a reduced lifespan when using power sources with large harmonics.

Advantages of harmonic filtering:

- Reduce power loss

- Increase the life of electrical equipment

- Transformer noise protection, capacitor explosion protection

- Prevent cable overheating

- Anti-interference, anti-noise

3. VG Group 's solution to improve power quality

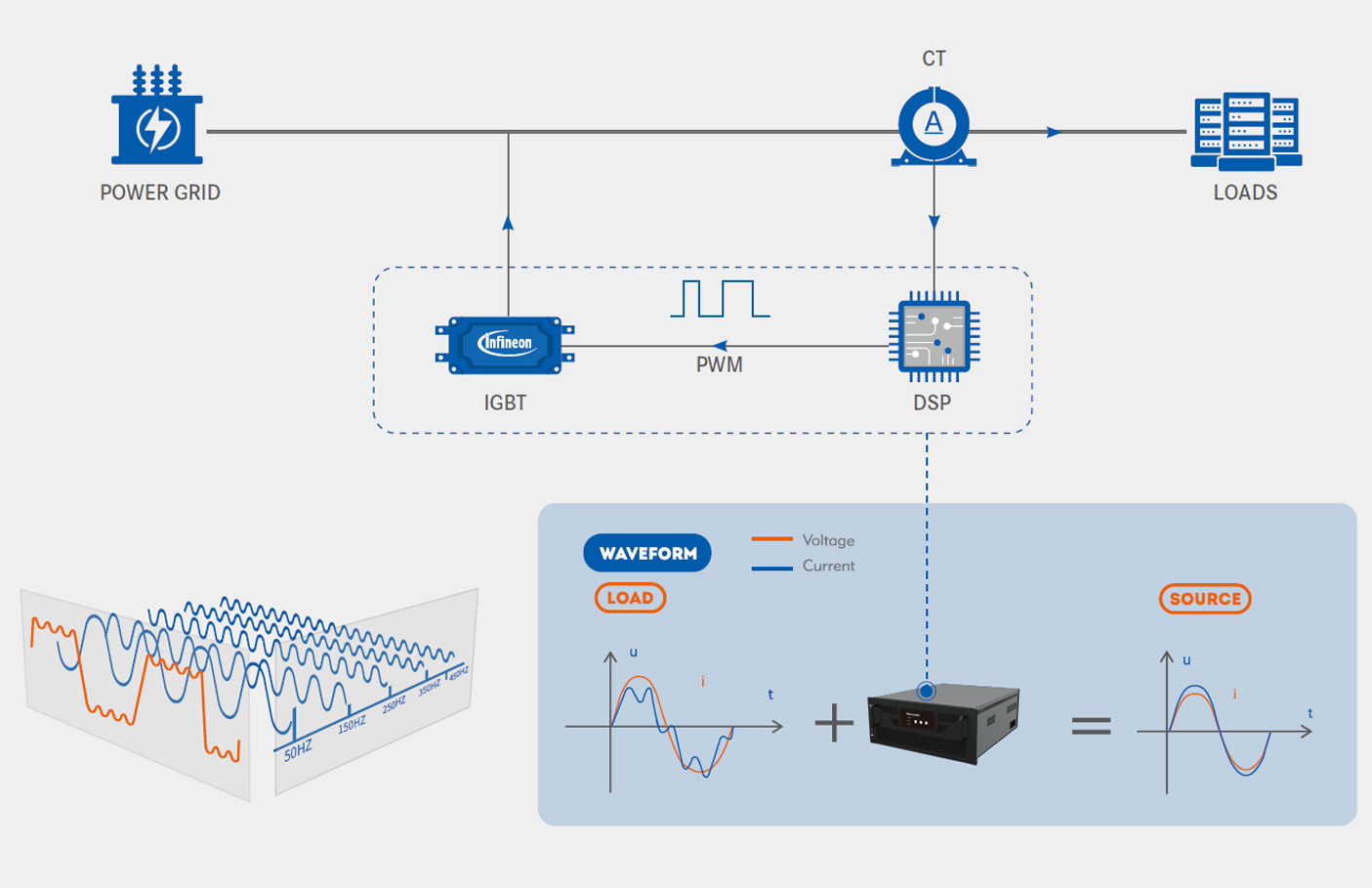

Active harmonic filtering is a solution implemented by VG Group to improve electricity quality, avoid incidents, and save electricity costs.

VG Group 's active harmonic filter applies the latest technology, controlling the IGBT through a microprocessor with FFT (Fourier Series) algorithm, helping to emit the right type of harmonics with the opposite phase angle to eliminate harmonics in system in real time. Thanks to this technology, harmonics are completely processed, eliminating potential dangers. The solution helps reduce line losses and avoid problems for customers.

VG Group offers an active harmonic filtering solution

Active harmonic filtering solution helps to completely solve harmonic problems such as cable heating, breakdowns, capacitor explosions, causing interference and minimizing the lifespan of production machinery, electrical loads, and line losses. wire. This solution also actively compensates reactive power to help customers save on electricity costs each month and reduce the possibility of being fined by electricity.

VG Group also supports customers with free electricity quality assessment and a two-year product warranty after installation.

The reliability and quality of the power source is one of the most important conditions for the operation of manufacturing plants, service buildings as well as hospitals or data centers. Harmonics are one of the power quality problems that cause frequent and long-term effects, causing power loss, fire and explosion, and negatively affecting the lifespan and efficiency of power supply.

Eliminating harmonics is like filtering clean water. Electricity customers always have headaches finding ways to solve the problem of harmonics and its consequences. " VG Group 's harmonic filtering and reactive power compensation solutions currently have a reasonable cost, only 50% of existing solutions on the market.